The operation, protection, and daily maintenance of the packaging machine are becoming increasingly convenient and simple.

Release Date:

2021-10-08

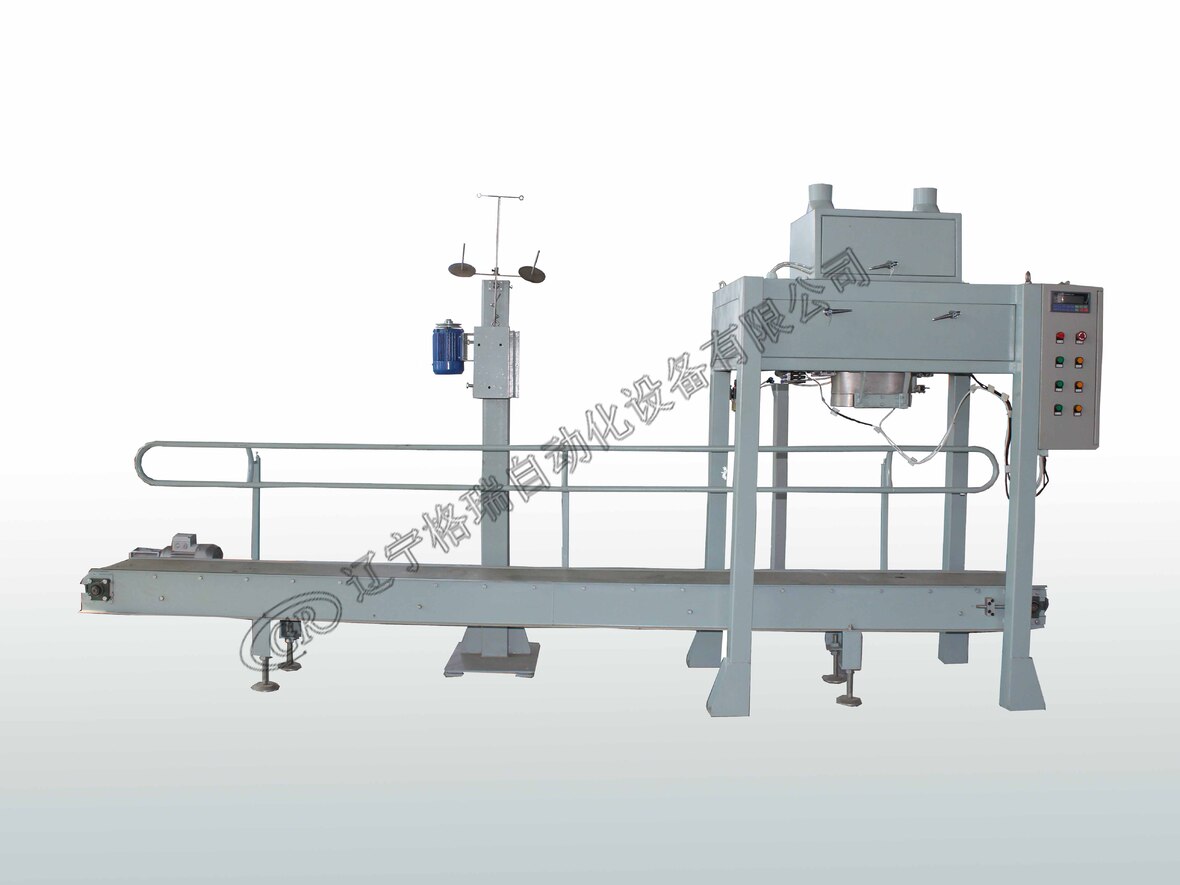

Packaging Machine

With the improvement of automation level, the operation, protection, and daily maintenance of packaging machines have become more convenient and simpler, reducing the professional skill requirements for operators. The quality of product packaging is directly related to the temperature system, the main machine speed accuracy, and the stability performance of the tracking system. After the machine starts running, the film mark sensor continuously detects the film marks (color marks), while the mechanical tracking micro switch detects the position of the machinery. These two signals are sent to the PLC, and after program calculation, the PLC outputs Y6 (forward tracking) and Y12 (reverse tracking) to control the forward and reverse tracking of the tracking motor. This timely detects errors in the packaging material during production and accurately compensates and corrects them, avoiding waste of packaging materials. If the detection cannot meet technical requirements after the preset number of tracking attempts, the machine can automatically stop for inspection to avoid defective products. The use of variable frequency speed regulation greatly reduces chain transmission, improves the stability and reliability of machine operation, and reduces noise. This ensures that the packaging machine has multiple functions such as low loss and automatic detection, achieving a fully automatic high technical level. Although the transmission system used in the automatic packaging machine is relatively simple in function, it has high requirements for dynamic performance, requiring fast dynamic follow-up performance and high steady speed accuracy.

Removes part of the air (oxygen) from the packaging container, effectively preventing food spoilage and deterioration.

Using barrier (airtight) packaging materials and strict sealing technology and requirements can effectively prevent the exchange of packaging contents, thus avoiding food weight loss and flavor loss, as well as secondary contamination. The gas inside the vacuum packaging container has been removed, accelerating heat conduction, which improves the effectiveness of thermal sterilization and prevents the packaging container from breaking due to gas expansion during heating sterilization.

In the food industry, vacuum packaging is widely used. Various cooked products such as chicken legs, ham, sausages, grilled fish slices, beef jerky, etc.; pickled products such as various sauces, bean products, candied fruits, and various other foods requiring preservation increasingly use vacuum packaging. Food packaged by vacuum packaging has a long shelf life, greatly extending the food's preservation period.

Feeding and discharging method: forward right discharge type. The compact vacuum packaging machine adopts a heat box fixed instantaneous heating method, saving energy. Special electric heating placement ensures even heat distribution. The machine is compact and occupies a small footprint. Suitable for small batch and medium batch production, it can cooperate with assembly line operations to improve the efficiency of vacuum packaging machines. Uses original imported parts from Taiwan, Japan, and South Korea, with stable and reliable performance.

(All the above content is sourced from the internet. If there are any issues, please contact me for removal)

Contact Information

Address: No. 3, Shendong 7th Road, Fushun Economic Development Zone

National Service Hotline:+86 24 58067727

General Office:+86 24 58067728

Sales Department:+86 15804137755

After-sales Service:+86 15004137328

Email:green@fsgreen.com