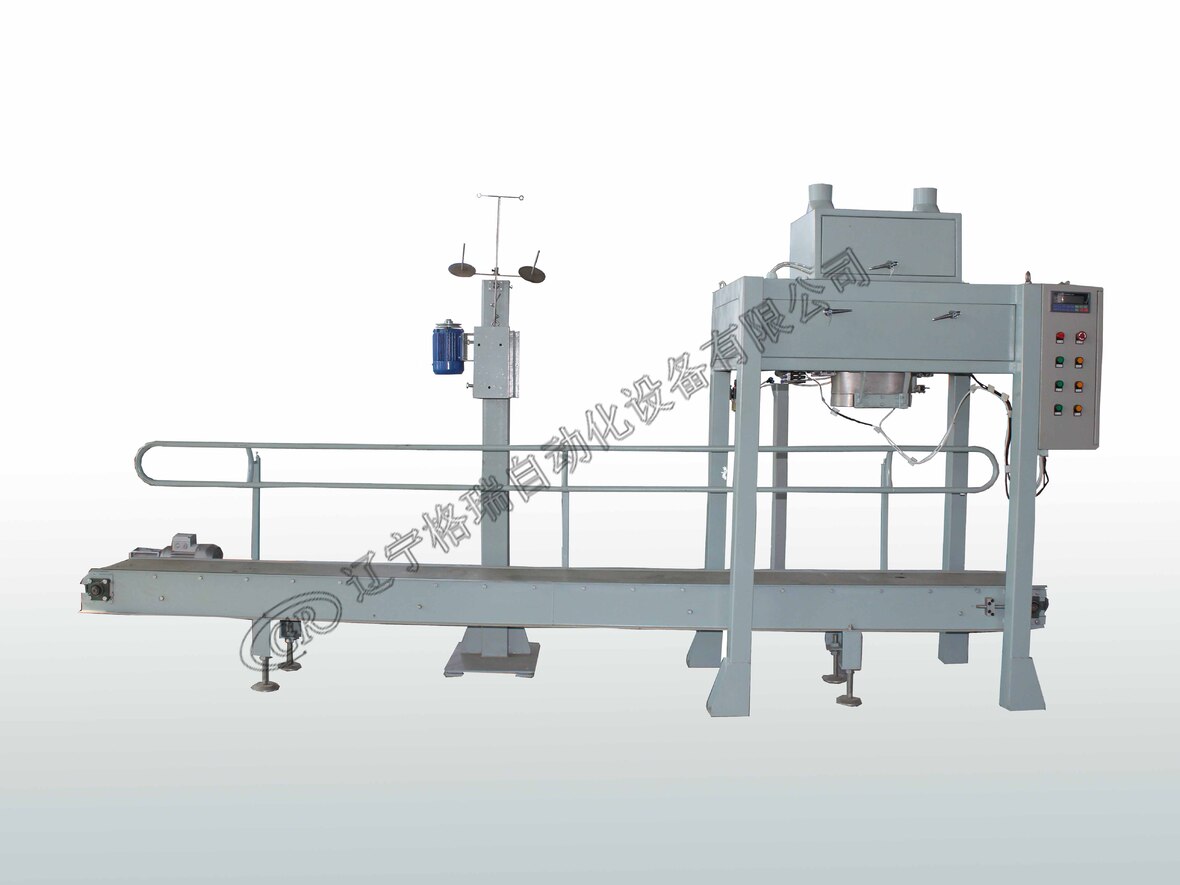

A fully automatic packaging machine generally consists of a bag feeder and a weighing machine.

Release Date:

2021-10-01

Fully automatic packaging machines in the domestic market mainly include three types: bag-making type, bag-feeding type, and can-feeding type. Here is an analysis of the differences and features of these three types of packaging machines. The bag-making fully automatic packaging machine generally consists of a bag-making machine and a weighing machine. The weighing machine can be either a weighing type or a screw type, capable of packaging granular and powder materials. This machine directly forms bags from packaging film and completes actions such as measuring, filling, coding, and cutting during the bag-making process. The packaging materials are generally plastic composite film, aluminum-platinum composite film, paper bag composite film, etc. Its features include a high degree of automation, high price, good appearance, and good anti-counterfeiting properties. It is suitable for small specifications and large-scale automated packaging of products such as laundry detergent, seasonings, and puffed foods. The drawback is that changing packaging specifications is not very convenient.

The bag-feeding fully automatic packaging machine generally consists of a bag feeder and a weighing machine. The weighing machine can be either a weighing type or a screw type, capable of packaging granular and powder materials. The working principle of this machine is to use a mechanical arm to pick up, open, sleeve, and seal the user's pre-made bags. At the same time, under the coordinated control of a microcomputer, it completes functions such as filling and coding, thus achieving automated packaging of pre-made bags. Its features include the mechanical arm replacing manual bagging, effectively reducing bacterial contamination during packaging, and improving the level of automation. It is suitable for small specifications and large-scale automated packaging of products such as food and seasonings. The drawback is that the pre-made bags must be free of static electricity; otherwise, double bags may be picked up and the bag opening may be inaccurate. Changing packaging specifications is also not very convenient for this machine. The can-feeding fully automatic packaging machine is mainly used for automated canning of cup-shaped containers such as tin cans and paper cans. The whole machine generally consists of a can feeder, a weighing machine, and a capping machine.

The can feeder generally adopts an intermittent rotary mechanism, sending a discharge signal to the weighing machine each time it rotates one station, completing one quantitative canning. The weighing machine can be either a weighing type or a screw type, capable of packaging granular and powder materials. The capping machine is connected to the can feeder via a conveyor belt; essentially, the two operate as linked single machines, working independently. This machine is mainly used for automated packaging of products such as chicken essence, chicken powder, malt extract, and milk powder. Its features include a high degree of automation, fewer contamination steps, high price, high efficiency, and good appearance. The drawback is that changing specifications is not very convenient. In addition, there are sealing and shrinking devices, filling and capping machines, counting machines, labeling machines, and special packaging equipment such as Qingdao Santian's mask machines and eye mask agents, all of which fall under the category of packaging machines.

(All the above content is sourced from the internet. If there are any issues, please contact me for removal)

Contact Information

Address: No. 3, Shendong 7th Road, Fushun Economic Development Zone

National Service Hotline:+86 24 58067727

General Office:+86 24 58067728

Sales Department:+86 15804137755

After-sales Service:+86 15004137328

Email:green@fsgreen.com